Chimney Liner Installation

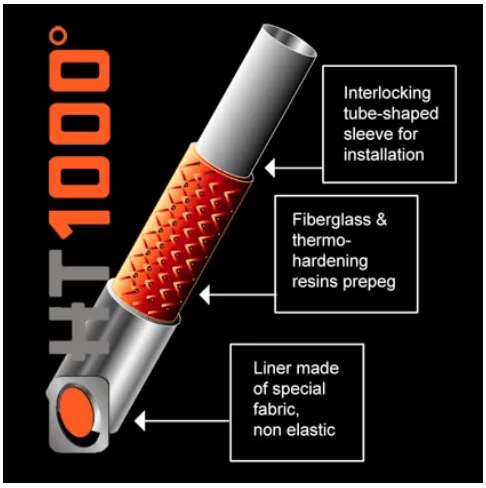

Thermosetting lining system for solid fuel and all flue types – HT1000

The new revolutionary remediation system for solid fuels such as wood, coal used in civil fireplaces, wood-burning ovens and industrial furnaces has the exceptional feature of being able to guarantee absolute incombustibility at high temperatures and to maintain its characteristics over time even at 1300 ° C continuously.

The main features are as follows:

- Complete adaptability of the system to all sections of the existing circular, oval, triangular or rectangular flue.

- Sheath diameters available from 50mm to 600mm

- Suitable for high operating temperatures 1300 ° C

- High barrier to fire and flame propagation.

- Completely incombustible material.

- Thermal insulation.

- Resistance to alkaline and acid agents.

HT1000 is based on ceramic fabrics impregnated with particular resins designed and manufactured for high temperatures.

Fields of application

Due to its particular characteristics, the new HT1000 system can be used in all situations where non-destructive rehabilitation of smoke channels at high temperatures up to 1300 ° C is required.

The high-tech material at these temperatures does not undergo any alteration and maintains its characteristics unaltered.

It is no coincidence that in the most common wood-burning fireplaces, the problem is not so much the temperatures of the fumes that can reach temperatures of around 700-800 ° C at the entrance, but the real problem is when soot deposits form along the duct which often it ignites bringing the flue wall temperature over 1000 ° C. Consequently it is absolutely necessary to have a completely incombustible material at high temperatures, in fact if it were not incombustible it would cause a fire or a break inside the duct itself, causing unimaginable consequences.

The most common fields of application are the following:

- Non-destructive rehabilitation of flues of:

- Wood Burning Fireplace

- Wood furnaces

- Industrial furnaces

- Pellet stoves

- Wood stoves

- Industrial furnaces

- Industrial ducts destined to high temperatures.

We specialise in the installation of chimney flue liners for all types of masonry chimney stacks.

Stainless steel liners are designed to enhance the safety and performance of various appliances, particularly wood burning or multi fuel stoves. Our experience has shown that stoves with liners perform better and are easier to control through the air vents.

Our flue liners are constructed with deeply corrugated BS 1449 316 grade stainless steel and are manufactured into a twin wall flue liner that combines great strength with flexibility. The outer corrugated layer provides a protective casing during the installation process and after installation, it helps protect the inner layer from corrosion due to attack by residual deposits. The inner layer is smooth to discourage the build-up of soot and other potentially corrosive residues and to encourage the unimpaired flow of flue gasses. The inner and outer layers are joined by the Triple Lock Joint System, which is acknowledged to be the best jointing system available. The Triple Lock Joint provides strength and stability by distributing forces evenly around the flue liner, and the overlapping joint construction protects the joint from the potentially damaging effects of condensation.

Our twin wall construction, with triple lock and overlapping joints, enables our liners to withstand operational temperatures of up to 750° C and short fire temperatures of up to 1000° C, such as in the case of a chimney fire.

We offer three types of steel liner: 316/316 Stainless Steel Liner, 904/316 Stainless Steel Liner, and 904/904 Stainless Steel Liner. Each type is designed for specific appliances and comes with a warranty of either ten or twenty years.

ISOKOAT

In old chimneys, the mortar joints between the bricks or stonework often fail, allowing poisonous fumes, tars, and condensation to leak out of the flue into the home. To address this issue, we offer the ISOKOAT flue coating and renovating system developed by ISOKERN. This system has been used in thousands of installations in Europe since the 1950s and has demonstrated its simplicity and reliability. ISOKOAT is applied under pressure and forced into the cracks and fissures, sealing them, re-pointing the joints, and making good the flue wall. The coating is built up using between two and four applications to provide a smooth, gas-tight flue that will withstand the effects of flue gases for years to come. The flue is fully repaired and sealed with virtually no reduction in size, which is crucial for maintaining the correct flue size for the open fire or appliance served by the chimney.

What is a flue liner?

A flue liner, also commonly known as a chimney liner, is a flexible tube that is connected to your stove pipe in order to line the inside of your chimney. It extends the entire length of your chimney, directing fumes up the flue liner instead of releasing them directly into the chimney cavity.

The incorporation of flue lining into your chimney system can prove to be a significant enhancement, contributing to the safety and efficiency of the structure. In instances where the chimney is older, it may lack lining altogether or necessitate relining due to wear and tear.

This is important as flue lining will prevent noxious gases, such as carbon monoxide, from seeping through cracks in your masonry and into your home.